Isistimu yokulayisha ibhokisi elizenzakalelayo

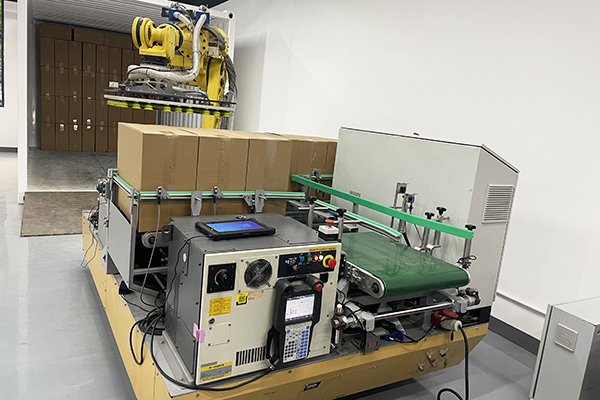

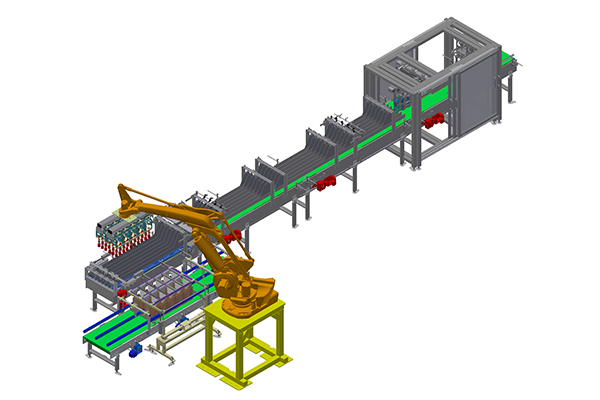

Okuzenzakalelayoukulayishwa kwebhokisiuhlelo,

ukulayishwa kwebhokisi,

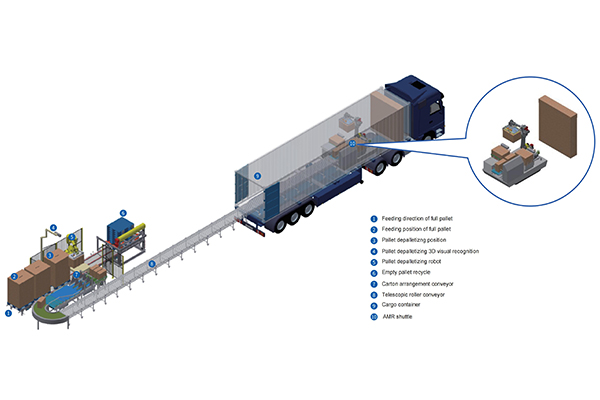

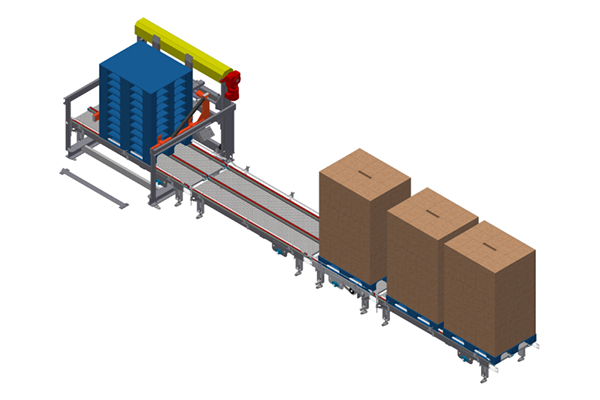

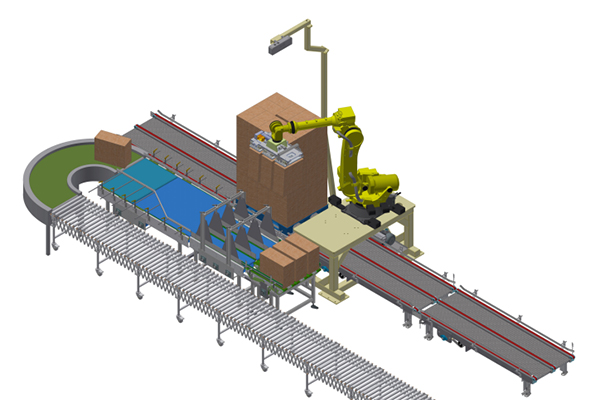

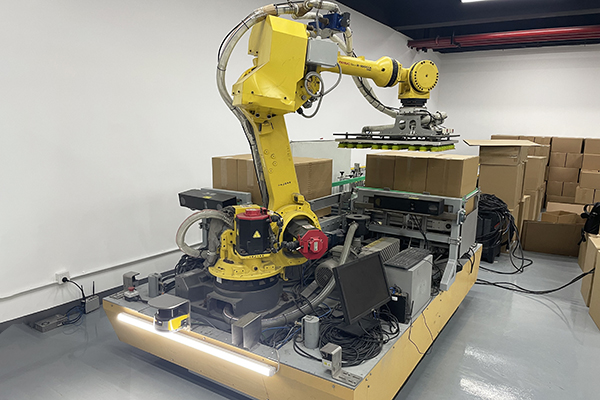

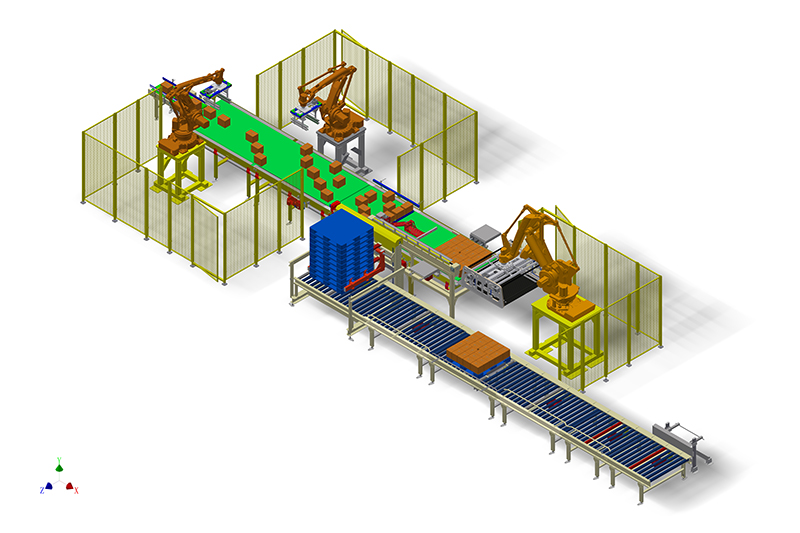

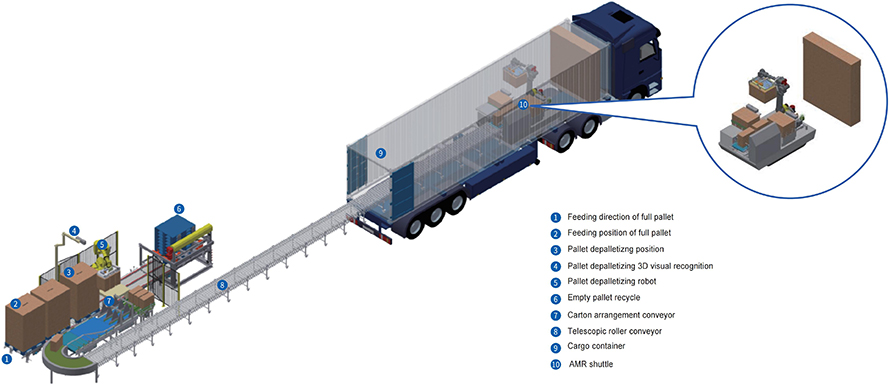

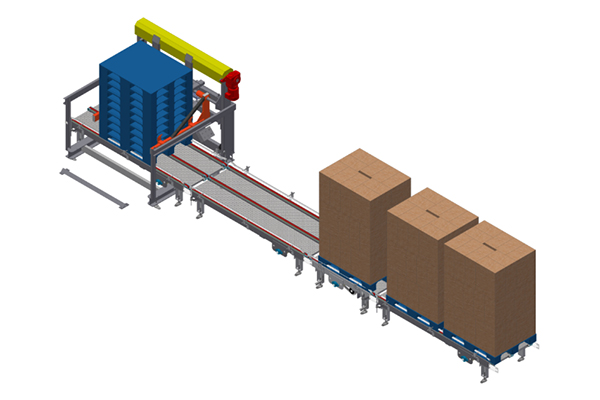

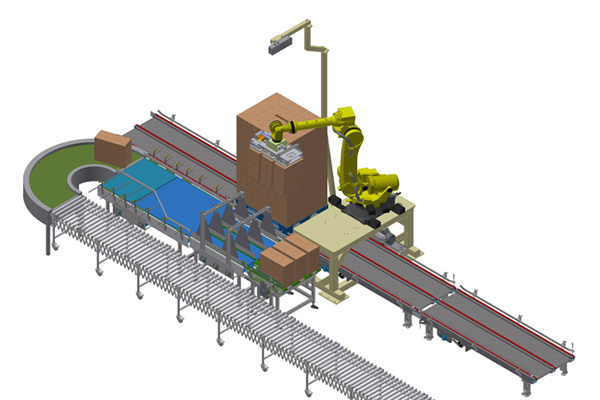

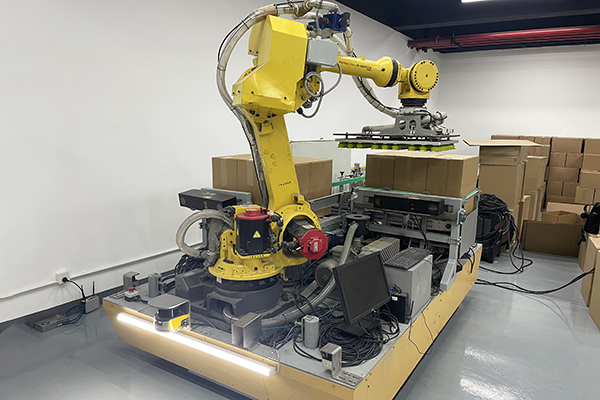

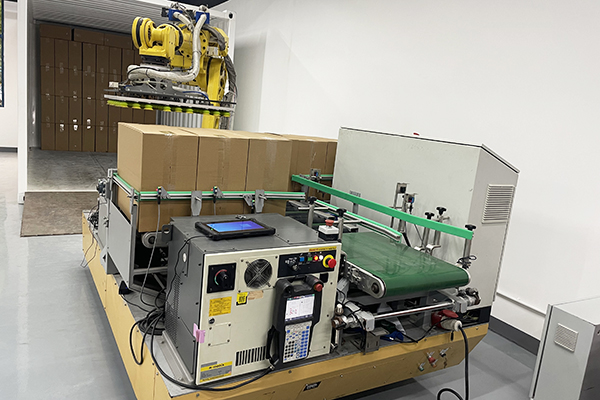

Idivayisi isebenzisa ikhamera ye-3D ukuze iskene isitaki futhi idatha yefu yephoyinti lokukhiqiza ibala izixhumanisi zendawo zendawo ephezulu yebhokisi. Irobhothi elikhipha amapallet lisusa amapallet ngokunembile ibhokisi ngokusekelwe kuzixhumanisi zendawo ezingaphezulu kwebhokisi. Ikhamera ye-3D ingaphinda iskene futhi ikhombe ukuthi indawo engaphezulu yebhokisi yonakele yini noma ingcolile. Irobhothi le-axis engu-6 lisetshenziselwa ukususa isitaki, liguqule umkhiqizo libe ngu-90 ° bese lisibeka. I-depalletizing gripper ingathola izinombolo zamabhokisi ezihlukene, njengamabhokisi ama-2 noma ama-3, ngokohlobo lwesitaki. Ingakwazi ukufeza isixazululo esizenzakalelayo sokususa amapallet okuzenzakalelayo, ukugaywa kabusha kwepallet okuzenzakalelayo, nokuphuma kwebhokisi okuzenzakalelayo. Ngemva kwalokho, lapho imoto ye-AMR izihambela ngokuzenzakalelayo nge-SLAMlidarnavigation futhi ihlale ilungisa ukuma komzimba, imoto ye-AMR ingagcina igxile enqoleni. Ikhamera ye-3D emotweni ye-AMR iskena idatha yendawo yenqola futhi ibuyisela izixhumanisi zendawo ekhoneni elingezansi kwesokudla lekhanda lenqola ukuya erobhothini elilayishayo. Irobhothi elilayishayo libamba amabhokisi futhi liwabeke phezu kwepallet ngokususelwe kuzixhumanisi zamakhona. Ikhamera ye-3D iskena izixhumanisi zamabhokisi astakwe irobhothi isikhathi ngasinye iphinde ibale amaphoyinti ekhona. Ibala ukuthi kuzoba khona yini ukushayisana nokuthi amabhokisi ayatsheka noma alimele yini ngesikhathi sokulayisha ngakunye. Irobhothi lilungisa ukuma kokulayisha ngokusekelwe kudatha yephoyinti lekhona elibaliwe. Ngemuva kokuthi irobhothi liphalele ohlangothini olulodwa, i-AMR vechile ihlehla ibanga elinqunywe kusengaphambili ukuze ilayishe umugqa olandelayo. Ilayisha ngokuqhubekayo futhi ihlehle kuze kube yilapho inqola igcwala amabhokisi. Imoto ye-AMR iphuma enqoleni futhi ilinda inqola elandelayo ukuthi ilayishe amabhokisi.

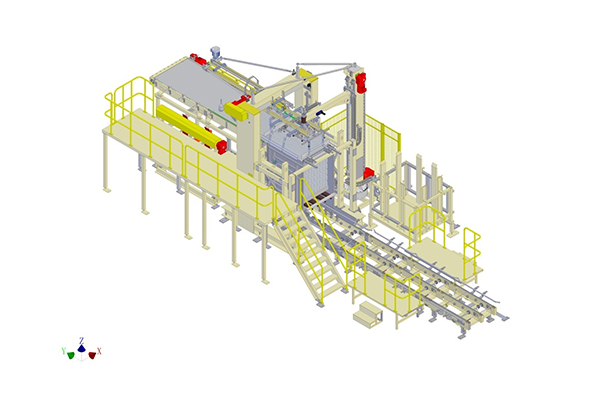

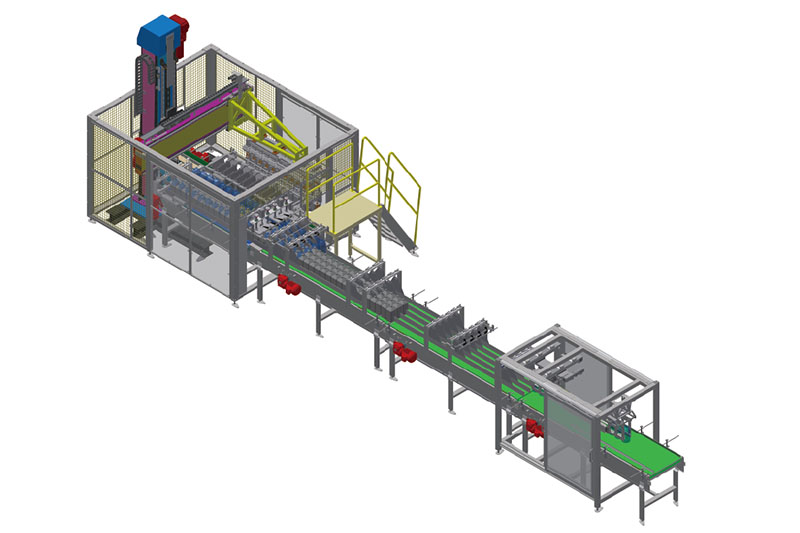

Isakhiwo esiphelele sesistimu yokupakisha

Ukucushwa okuyinhloko

| Ingalo yerobhothi | ABB/KUKA/Fanuc |

| Imoto | I-SEW/Nord/ABB |

| I-Servo motor | Siemens/Panasonic |

| I-VFD | I-Danfoss |

| I-Photoelectricsensor | OGULAYO |

| Isikrini sokuthinta | Siemens |

| I-voltage ephansi | Schneider |

| Isikhumulo | Phoenix |

| I-pneumatic | I-FESTO/SMC |

| I-Suckingdisc | I-PIAB |

| Ukuzala | I-KF/NSK |

| Iphampu ye-vacuum | I-PIAB |

| I-PLC | Siemens / Schneider |

| HMI | Siemens / Schneider |

| I-chain plate/chain | Intralox/rexnord/Regina |

Incazelo yesakhiwo esiyinhloko

Imidlalo yamavidiyo engeziwe

- I-Automatic Container Loadin System (Ifakwe Ngemoto Elandelwayo ye-AMR)

Isistimu yokulayisha irobhothi iyakwazi ukulungisa ngokuguquguqukayo ibanga lezokuthutha, ifake amaloli anobude obuhlukahlukene, futhi yenze izinto zokuhamba nge-telescopic. Lungisa isimo sengqondo sezimpahla ngokuzenzakalelayo ukuze ulondoloze ukuzinza kokulayisha. Isimo esinembile kanye nokuzimisela kwesimo sengqondo sezimpahla kutholakala ngokusebenzisa ubuchwepheshe bombono we-3D. Hlanganisa isistimu yenqolobane, gcina izinto okwesikhashana, vumelanisa umugqa wokukhiqiza, futhi ulungise izinga lokulayisha.